The bottom of the plastic bottle is recessed to allow the beverage bottle to stand firmer. If it is a flat-bottomed plastic bottle, it is easily deformed due to the hydraulic pressure, and it usually protrudes outward, so that the beverage bottle is not stable. However, if the bottom is designed in the shape of a groove, the stress area of the bottom is increased, and the pressure is reduced, so that it is not easy to deform. And even if the entire bottom does not touch the table, as long as the force is uniform, it can stand very stably. The stability of the five-claw shape is very good, so a large part of the common plastic bottles are made into a five-claw shape. Plastic bottles are usually only disposable. If you use it to hold hot water, you will notice that it will deform and either bulge or shrink. In addition to becoming strangely shaped and difficult to stand, plastic products also release toxic substances at high temperatures.

The bottom of the plastic bottle is recessed to allow the beverage bottle to stand firmer. If it is a flat-bottomed plastic bottle, it is easily deformed due to the hydraulic pressure, and it usually protrudes outward, so that the beverage bottle is not stable. However, if the bottom is designed in the shape of a groove, the stress area of the bottom is increased, and the pressure is reduced, so that it is not easy to deform. And even if the entire bottom does not touch the table, as long as the force is uniform, it can stand very stably. The stability of the five-claw shape is very good, so a large part of the common plastic bottles are made into a five-claw shape. Plastic bottles are usually only disposable. If you use it to hold hot water, you will notice that it will deform and either bulge or shrink. In addition to becoming strangely shaped and difficult to stand, plastic products also release toxic substances at high temperatures.

2019年11月28日星期四

Why is the bottom of the plastic bottle recessed

The bottom of the plastic bottle is recessed to allow the beverage bottle to stand firmer. If it is a flat-bottomed plastic bottle, it is easily deformed due to the hydraulic pressure, and it usually protrudes outward, so that the beverage bottle is not stable. However, if the bottom is designed in the shape of a groove, the stress area of the bottom is increased, and the pressure is reduced, so that it is not easy to deform. And even if the entire bottom does not touch the table, as long as the force is uniform, it can stand very stably. The stability of the five-claw shape is very good, so a large part of the common plastic bottles are made into a five-claw shape. Plastic bottles are usually only disposable. If you use it to hold hot water, you will notice that it will deform and either bulge or shrink. In addition to becoming strangely shaped and difficult to stand, plastic products also release toxic substances at high temperatures.

The bottom of the plastic bottle is recessed to allow the beverage bottle to stand firmer. If it is a flat-bottomed plastic bottle, it is easily deformed due to the hydraulic pressure, and it usually protrudes outward, so that the beverage bottle is not stable. However, if the bottom is designed in the shape of a groove, the stress area of the bottom is increased, and the pressure is reduced, so that it is not easy to deform. And even if the entire bottom does not touch the table, as long as the force is uniform, it can stand very stably. The stability of the five-claw shape is very good, so a large part of the common plastic bottles are made into a five-claw shape. Plastic bottles are usually only disposable. If you use it to hold hot water, you will notice that it will deform and either bulge or shrink. In addition to becoming strangely shaped and difficult to stand, plastic products also release toxic substances at high temperatures.

2019年4月26日星期五

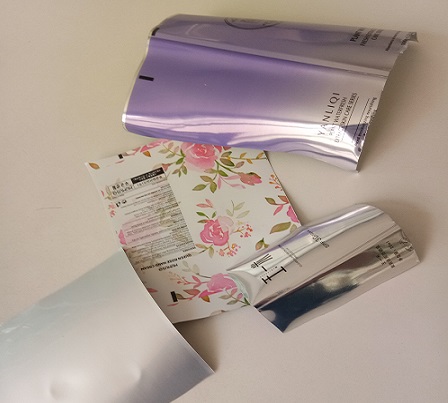

Material introduction of cosmetic aluminum-plastic tube

Material introduction of cosmetic aluminum-plastic tube

There are five main materials for cosmetic aluminum-plastic tubes: ordinary silver sheets, ordinary white sheets, high-gloss sheets (also called high-bright sheets), all-plastic transparent sheets, and fully-shaped white sheets. The five kinds of sheets have their own characteristics. The biggest difference is that the printing effect is different. The common point is that the printing effect is very realistic.

In addition, each material has different thicknesses. The most commonly used thickness specifications for cosmetic packaging are: 250μm, 270μm, 300μm, 330μm, 350μm, 400μm, and materials exceeding 400μm. The production process is very demanding, many manufacturers cannot make it. 350μm materials are commonly found in high-end cosmetic packaging, such as facial cleanser, sunscreen, etc. Sheets below 300 μm are generally found in hand cream tubes, toothpaste tubes, and the like.

订阅:

博文 (Atom)